While it's still possible, at the time of this writing, to download a copy of CB Model Pro, it's become plain that it will probably never see the light of day as a full product.

I will miss it.

But, Dassault Systemes, the publisher of CB Model Pro has introduced something even better! 3DVia!

http://www.3dvia.com

I urge you to take a good hard look at it. Our CB Model Pro community was rather small. By comparison, the 3DVia community is growing by leaps and bounds. That is because the product is great for beginners to experts.

We can thank some on the CB Model Pro team for the great work they've also done on 3DVia. Check out their great work.

Lastly, I want to thank all of you that sent messages of thanks for the tutorials. I loved doing them and I was always happy to hear that they were of value to you. But, the time has come to move on to the next generation of consumer 3D products.

See you over on the 3DVia site!

Monday, August 31, 2009

Tuesday, May 22, 2007

Creating delicate features in CB Model Pro

When sending a model to be printed in 3D, it's wise to reduce the volume of the model. As I was experimenting with techniques to do this, I found that I could create much more delicate models than I had previously thought in CB Model Pro.

In the first video, I demonstrate some techniques for reducing volume of the object and also demonstrate just how delicately the CB Model Pro engine can work. As usual, it's a demo and I'm pressed to complete it as quickly as possible, so you should be able to do a much better job by taking more time. This one is probably too thin to safely print in 3D. But, it does demonstrate the concept.

Play the Finer Work Demonstration

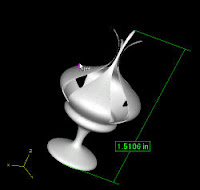

Preparing an object for 3D printing usually starts by exporting it. Most of the 3D printers can use an STL file format. Here is what our model looks like when exported in the STL file format.

Play the STL Reader Demonstration

The ability to export our models in various file formats is a wonderful capability that permits us to use our models in a variety of ways, from animations to actual 3D hard objects. Nice.

Thursday, May 17, 2007

It's coming! 3D Printing for 3D fans

I've been drooling over the concept of 3D printing for some time now. But, had never actually seen the output. I recently learned that there was service bureau near my home that had a 3D printer so I decided to stop by and see if they had any samples.

I've been drooling over the concept of 3D printing for some time now. But, had never actually seen the output. I recently learned that there was service bureau near my home that had a 3D printer so I decided to stop by and see if they had any samples.They did. And, very impressive ones at that! I'm sold.

But, being sold doesn't mean that I can afford one just now. Z-Corp's Z-450 is around $40,000 which puts it a well beyond my budget. But, there is hope.

Cornell's Fab@home Project is a low-cost experimental 3D fabricator. While it relies on extrusion to create 3D items, it still looks fun. But, I'd really like something closer to what the big guys have.

That's where the V-Flash and Desktop Factory come in. They claim to be releasing lower cost 3D printing solutions sometime this summer. The V-Flash will be introduced at $9,900 and the Desktop Factory is projected to be $5,000. While not cheap, these prices represent a significant breakthrough.

From what little I've been able to learn, the V-Flash printer seems to produce the higher resolution while the Desktop Factory is certainly the most affordable. The V-Flash is from a well established 3D fabricator manufacturer and the samples seem to have a much finer surface than those seen on the Desktop Factory web site. I came across a discussion that included some remarks from someone that had seen the V-Flash in action. I haven't verified that the information is completely accurate; but, it appears that it is. Here is a link:

http://rapid.lpt.fi/rp-ml-current/0244.html

The company building the Desktop Factory claims that their aim is to get the price down to around a $1,000 in four years. If and when this happens, and I have no doubt that SOMEONE will, it's going to revolutionize many things that we can't even comprehend just now. Education and art are definitely going to be impacted in a huge way.

It's coming and the prices are coming in our direction!

Cosmic Blobs and CB Model Pro users might be among the first to benefit by 3D printing. Check out the CosmicModelz site!

I want one!!! In fact, I've already created the CB Model Pro object that I'd like to run as my first test. It's the chalice in the above image. There are a number of purposely created cuts and, while you can't see it in the image, it's got a hollow center. It's not a solid object. And, the base is also slightly hollowed underneath. If and when I have it made, I'll post it here. I might wait until the servicde bureau gets in their expected Z450.

UPDATE

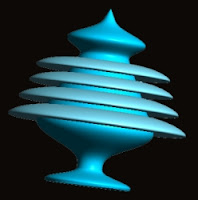

When sculpting in clay, certain things can only be done completely by hand, since undercuts prevent casting. I've tried to simulate this situation in these two CB Model Pro models that I plan to have printed using a 3D printer. In this sample, the problem is that the horizontal bands bend downward. This would make it difficult to use a mold, since the mold would become trapped by the shape, itself. It's simple task for a 3D printer. However, I have learned that I really need to make the bands thinner, to lower the cost of printing.

The next sample demonstrates a particularly difficult problem for a clay sculpture. It seems to consist of two individual pieces. The first is a shaft, closed on both ends and the second is a spool-like form that freely rotates and slips up and down on the shaft. To do this in clay one would probably choose to glue the top cap into the shaft after it was fired since the pieces might actually fuse during firing.

However, a powder based 3D printer can easily recreate it as a single print job. Loose powder between the shaft and spool would support the spool as it was being built.

Note that a slight gap exists in the model between the shaft and the hole in the spool. It's going to be interesting to see how this turns out.

I plan to keep track of both of the new low cost printers and will update information as it's available.

Tuesday, May 8, 2007

How I learn CB Model Pro

Thomas Haak, a CB Model Pro user from Germany asks how much time I spend in Cosmic Blobs and CB Model Pro. The answer is that I don't really know. Most of my time in the products is spent as diversionary time, much as people play FreeCell or Solitaire.

Thomas Haak, a CB Model Pro user from Germany asks how much time I spend in Cosmic Blobs and CB Model Pro. The answer is that I don't really know. Most of my time in the products is spent as diversionary time, much as people play FreeCell or Solitaire.I learn by taking a few minutes several times a day... mostly while other processes are running in the background. In these mini-sessions I have absolutely nothing in mind except for experimentation with free form, abstract sculpting. I've saved a short session in hopes that it gives others some ideas for simply playing around in CB Model Pro to learn the behaviour of combinations of tools and shapes.

Play the Free-Form Mini-Session

As you can see, when exploring the capabilities of Cosmic Blobs or CB Model Pro, sometimes it's fun NOT to have any goal other than forming itself.

Monday, May 7, 2007

CB Model Pro - Cubes Aren't Just for Squares!

Some shapes are more difficult than others to visualize creative outcomes. The cube is one of those shapes for me. But, that doesn't mean it can't be done. For instance, in this project we create a table and part of a chair completely from cubes. Moreover, most of the edges end up not being parallel!

Some shapes are more difficult than others to visualize creative outcomes. The cube is one of those shapes for me. But, that doesn't mean it can't be done. For instance, in this project we create a table and part of a chair completely from cubes. Moreover, most of the edges end up not being parallel!We use the Neck, Bend and Scale tools to manipulate our cubes.

Play the Tutorial for the Cubes to Table Project

In the interest of time we simply demonstrated part of a chair back. It's late and I'm lazy. But, the good news is that if you are using CB Model Pro, you've already proven that you're smart enough to figure out how to finish that chair.

Thursday, May 3, 2007

CB Model Pro - Cones Shed Some Light

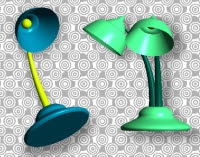

OK. It was a bad joke. But, I couldn't help myself. So, I'll just keep on going and say that in this mini-project tutorial we'll shed some light on creating a lamp using only the basic cone blob.

OK. It was a bad joke. But, I couldn't help myself. So, I'll just keep on going and say that in this mini-project tutorial we'll shed some light on creating a lamp using only the basic cone blob. Play the Tutorial for the Cones to Lamp Project

The Bend Tool, the Neck Tool and the Flatten Tool play prominent parts in helping us to form a desk lamp. It's not exciting; but, it does show three distinctly different outcomes for three different cones. And, it shows how we move the fulcrum of the bend tool to specify the primary bend point along our object.

CB Model Pro Project - From Cylinder to Invading Armada

Among the basic 'blobs' in CB Model Pro, the cylinder might appear to be the most bland. It's difficult to visualize just how versatile it can be when all the CB Model Pro tools are applied to it. How could one be expected to guess that the unexciting and static cylinder would be used by marauding aliens to create this sweeping attack armada???

Among the basic 'blobs' in CB Model Pro, the cylinder might appear to be the most bland. It's difficult to visualize just how versatile it can be when all the CB Model Pro tools are applied to it. How could one be expected to guess that the unexciting and static cylinder would be used by marauding aliens to create this sweeping attack armada??? OH, The Humanity!!!!

Play the Tutorial for the Cylinder to Invading Armada Project

All the tools are used in this short tutorial. But, the Neck and Bend tools are the real keys used in shaping the model in this particular transformation of the cylinder. They are equally wonderful tools to use when experimenting with creating beautiful flowing sculptural shapes.

Subscribe to:

Posts (Atom)