I've been drooling over the concept of 3D printing for some time now. But, had never actually seen the output. I recently learned that there was service bureau near my home that had a 3D printer so I decided to stop by and see if they had any samples.

I've been drooling over the concept of 3D printing for some time now. But, had never actually seen the output. I recently learned that there was service bureau near my home that had a 3D printer so I decided to stop by and see if they had any samples.They did. And, very impressive ones at that! I'm sold.

But, being sold doesn't mean that I can afford one just now. Z-Corp's Z-450 is around $40,000 which puts it a well beyond my budget. But, there is hope.

Cornell's Fab@home Project is a low-cost experimental 3D fabricator. While it relies on extrusion to create 3D items, it still looks fun. But, I'd really like something closer to what the big guys have.

That's where the V-Flash and Desktop Factory come in. They claim to be releasing lower cost 3D printing solutions sometime this summer. The V-Flash will be introduced at $9,900 and the Desktop Factory is projected to be $5,000. While not cheap, these prices represent a significant breakthrough.

From what little I've been able to learn, the V-Flash printer seems to produce the higher resolution while the Desktop Factory is certainly the most affordable. The V-Flash is from a well established 3D fabricator manufacturer and the samples seem to have a much finer surface than those seen on the Desktop Factory web site. I came across a discussion that included some remarks from someone that had seen the V-Flash in action. I haven't verified that the information is completely accurate; but, it appears that it is. Here is a link:

http://rapid.lpt.fi/rp-ml-current/0244.html

The company building the Desktop Factory claims that their aim is to get the price down to around a $1,000 in four years. If and when this happens, and I have no doubt that SOMEONE will, it's going to revolutionize many things that we can't even comprehend just now. Education and art are definitely going to be impacted in a huge way.

It's coming and the prices are coming in our direction!

Cosmic Blobs and CB Model Pro users might be among the first to benefit by 3D printing. Check out the CosmicModelz site!

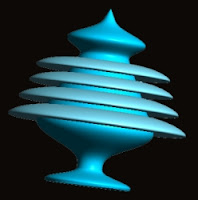

I want one!!! In fact, I've already created the CB Model Pro object that I'd like to run as my first test. It's the chalice in the above image. There are a number of purposely created cuts and, while you can't see it in the image, it's got a hollow center. It's not a solid object. And, the base is also slightly hollowed underneath. If and when I have it made, I'll post it here. I might wait until the servicde bureau gets in their expected Z450.

UPDATE

When sculpting in clay, certain things can only be done completely by hand, since undercuts prevent casting. I've tried to simulate this situation in these two CB Model Pro models that I plan to have printed using a 3D printer. In this sample, the problem is that the horizontal bands bend downward. This would make it difficult to use a mold, since the mold would become trapped by the shape, itself. It's simple task for a 3D printer. However, I have learned that I really need to make the bands thinner, to lower the cost of printing.

The next sample demonstrates a particularly difficult problem for a clay sculpture. It seems to consist of two individual pieces. The first is a shaft, closed on both ends and the second is a spool-like form that freely rotates and slips up and down on the shaft. To do this in clay one would probably choose to glue the top cap into the shaft after it was fired since the pieces might actually fuse during firing.

However, a powder based 3D printer can easily recreate it as a single print job. Loose powder between the shaft and spool would support the spool as it was being built.

Note that a slight gap exists in the model between the shaft and the hole in the spool. It's going to be interesting to see how this turns out.

I plan to keep track of both of the new low cost printers and will update information as it's available.

No comments:

Post a Comment